Sandvik QJ341 Mobile Jaw Crusher – World Leading Jaw Crusher

1,200 x 750 mm (47 x 29 in.) Max. feed size. 650 mm (26 in.) Capacity. 400 mtph (440 stph) Sandvik QJ341 mobile jaw crusher is the ideal solution for a wide range of applications.

Terex Minerals Processing Systems JW SERIES JAW

2023年7月14日 JW Series Jaw Crusher Enquiry Details 15 When enquiring about the range of Terex® JW Series Jaw Crushers please supply the following details so that the

Industrial Solutions Jaw crushers - ThyssenKrupp

2022年11月21日 Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being

What Is A Jaw Crusher - MEKA

1.) Obtaining the size or surface area required for the use of the ore or material. 2.) Allowing ease of transportation and storage. 3.) Separating the different minerals contained within

Jaw Crushers – MEKA

DESCRIPTIONS. ABOUT Jaw Crusher. DOWNLOADS. APPLICATIONS. Primary and secondary crushing applications for quarrying, mining, recycling and industrial minerals.

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 A hydraulic jaw crusher is a type of jaw crusher that uses hydraulic pressure to crush materials. It has a movable jaw that is operated by an eccentric shaft,

Jaw Crushers – Sandrock Mining

2024年3月28日 Jaw Crushers – Sandrock Mining. Raw materials: Granite, limestone, basalt, shale, river stone, bluestone, sandstone, calcium carbide, iron ore, cooper, steel

What Are The Pros And Cons Of Jaw Crushers? - Mormak

The basic technology behind jaw crushers has been around for almost 200 years, although it has undergone all manner of refinements and improvements to make it more efficient

Jaw crusher, Jaw crushing and screening plant - All industrial ...

jaw crusher BR380JG-3. mobile. Capacity: 50 t/h - 240 t/h. Motor power: 159 kW. Opening height: 1,065 mm. Eco-friendly performance moving to a new stage. The operating

Mengenal Mesin Jaw Crusher Secara Mendalam –

2021年5月24日 Mesin jaw crusher seringkali diasosiasikan dengan mesin stone crusher yang paling efektif dan efisien dibandingkan dengan jenis stone crusher lainnya. Mesin jaw crusher cocok digunakan untuk

KEMCO JAW CRUSHER - KOTOBUKI ENG. MFG.Co.,Ltd.

2022年5月17日 Overseas department. 1-2-2 Hiroshiratake, Kure-city, Hiroshima 737-0144 JAPAN. TEL : +81-823-73-1136.

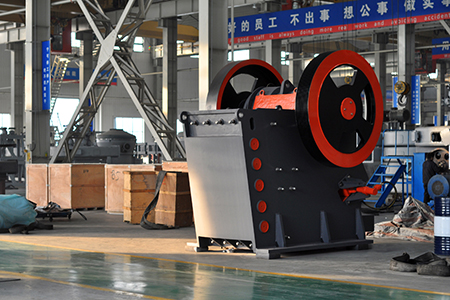

Jaw Crusher--Henan Zhongke Engineering Technology

Tel: +86 13526524173 E-mail: liusteven@cnzhongke. 1) Brief introduction of jaw crusher machine: Jaw crusher is widely used in construction, mining, chemical industries and other industries which need a powerful machine to crush rocks and stones. Generally, jaw crusher can be used for both primary and secondary crushing.

Laboratory Jaw Crusher – Labtech Group

Standards: ASTM C289. Laboratory jaw crushers allow you to process hard materials in extremely small sizes. In this sense, the laboratory type jaw crusher allows product output between 0 and 5 mm. You can also achieve higher product output by adjusting the grain size. The laboratory jaw crusher is built to create a high user experience.

ponsel jaw crusher untuk dijual afrika selatan crusher afrika ...

Contribute to luoruoping/id development by creating an account on GitHub.

The Ultimate Guide to Jaw Crushing Machines: Types

2023年2月21日 A hydraulic jaw crusher is a type of jaw crusher that uses hydraulic pressure to crush materials. It has a movable jaw that is operated by an eccentric shaft, as well as a fixed jaw that is positioned opposite the movable jaw. The hydraulic system allows the jaw to open and close, providing a wider range of crushing settings.

Jaw Crushers - FAQ - Comprehensive Jaw Crusher Guide

A jaw crusher is a crucial component in mining and ore processing plants, performing the primary crushing of rock and mineral ore to reduce and control the size of materials for further sizing, shaping, beneficiation and processing. These compression crushers are designed to tackle dry to slightly wet materials, without stickiness, and are ...

Mobile jaw crusher - Download Free 3D model by Lassi

2023年8月19日 Lokotrack LT96 is Metso’s most compact mobile jaw crusher. It is ideal for small scale on-site crushing, such as crushing demolition waste and aggregates production on construction sites. Photos taken with A7Riv + Sony 20mm and DJI Air2s Processed with Metashape + Blender - Mobile jaw crusher - Download Free 3D model by Lassi

ru/jepang jaw crusher ponsel.md at main runtu2/ru

Contribute to runtu2/ru development by creating an account on GitHub.

Jaw Crusher Working Principle - 911 Metallurgist

2021年5月6日 The jaw crusher discharge opening is the distance from the valley between corrugations on one jaw to the top of the mating corrugation on the other jaw. The crusher discharge opening governs the size of finished material produced by the crusher. Measuring Discharge Opening: Measure distance at bottom of jaws at the point of the crushing cycle

Jaws Mini combo Crusher – Jaws Mini Crushers

The Jaws Mini Crusher is designed to deal with a multitude of site waste, reducing all materials to skips, reusing them on site or even being sold on as a usable product!Never before has a machine been so versatile. The

Cedarapids JW42 Jaw Crusher - Terex MPS

2024年4月11日 The Cedarapids® CRJ3042 plant combines the popular JW42 jaw crusher with a high stroke, 42” x 20’ (1067 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine. Learn More about CRJ3042; MJ42. The MJ42 features the rugged JW42 Jaw Crusher for high production applications.

What is the role of 'jaw crusher' in the construction industry ...

2023年9月30日 Jaw Crusher Working Principle: Unlocking the Secrets of Efficiency. Jaw crushers are robust pieces of equipment that utilize mechanical pressure to crush rocks and minerals, offering several benefits in the construction and mining industries. Understanding their working principle sheds light on why they are essential assets in various projects.

Jaw Crusher Diagram: Simplified Guide - JXSC

2024年2月18日 A jaw crusher is an indispensable tool in the mining and construction industries, known for its power to fragment hard materials such as rock and minerals. Comprising type of jaw crusher—the robust Single-toggle and the efficient Double-toggle—these hefty machines operate on the principle of compressing materials between

id/ton crusher kerucut ponsel per jam.md at main lqdid/id

Contribute to lqdid/id development by creating an account on GitHub.

Crushers - Caldas Engineering and Manufacturing Services (Pty

CALDAS 400X600 SKID MOUNTED JAW CRUSHER. Our skid-mounted 400x600 crusher is the ultimate portable crusher that is easy to operate with our high-performance 400x600 Jaw Crusher. This includes a vibrating feeder, jaw crusher, 600mm discharge belt, and plug-and-play electrical system that is easy to use and safe for all sites. CQ 400x600 crusher.

pabrik mesin jaw crusher ponsel terus menerus

Contribute to lqdid/id development by creating an account on GitHub.

JAW CRUSHERS - McCloskey International Limited - PDF

McCloskey has a proven reputation for designing quality, The recirculating models produce a crushed and best-in-class equipment and the jaw crusher range screened final product with one machine, or the return brings more power and versatility together to deliver high conveyor can be radialed to the side to stockpile rather production. With its class-leading

ru/ponsel portabel crusher.md at main tualmenteyxh/ru

Contribute to tualmenteyxh/ru development by creating an account on GitHub.

Cedarapids JW55 Jaw Crusher - Terex MPS

6 天之前 The Cedarapids® CRJ3255 plant combines the popular JW55 jaw crusher with a high stroke, 52” x 20’ (1321 x 6096 mm) vibrating grizzly feeder resulting in a high production portable crushing machine. Learn More about CRJ3255; JS4552. The JS Series jaw crushers are built even more rugged and are easier to use. We have taken our jaw