A process for beneficiation of low-grade manganese ore and

2021年2月1日 Low-grade manganese ore is beneficiated with hydrochloric acid as a leaching agent to obtain a manganese concentrate. Hydrochloric acid can then be regenerated using cheaper sulfuric acid via contact with the leach liquor (a CaCl 2

A process for beneficiation of low-grade manganese ore and

2021年2月1日 Low-grade manganese ore is beneficiated with hydrochloric acid as a leaching agent to obtain a manganese concentrate. Hydrochloric acid can then be

Comprehensive Study on Mineral Processing Methods and

2024年2月26日 It provides the theoretical basis for the development and utilization of manganese ore in the later stage, provides the process mineralogy support for the

(PDF) BENEFICIATION OF LOW GRADE

2016年9月12日 Significant variability in ore grades and mineralogical characteristics impose challenges during selection of a proper

A Review of Low Grade Manganese Ore Upgradation Processes

2019年7月29日 ABSTRACT. Increased demand for manganese alloys and compounds for various industries created a dire need of Manganese (Mn) ore beneficiation technology.

Beneficiation of Manganese Ore Using Froth Flotation

2019年1月1日 Froth flotation is the process generally recommended for the beneficiation of low and medium grade ores because of the floatability characteristics of the manganese.

(PDF) Studies on Beneficiation of Manganese Ore through

2020年6月20日 Studies on Beneficiation of Manganese Ore through High Intensity Magnetic Separator. June 2020. Advances in Sciences and Engineering. License. CC BY

A review of the beneficiation of low-grade manganese ores ...

2020年1月12日 Magnetic separation is an effective strategy for the upgrading of a variety of lean ores, including the beneficiation of low-grade manganese ores.

The optimization of Sumbawa manganese ore beneficiation

2021年6月24日 Share. Tools. The beneficiation of manganese ore from Sumbawa, West Nusa Tenggara, Indonesia has been carried out by leaching method using sulfuric acid

Effect of desliming on the magnetic separation of low

2017年8月29日 Beneficiation flow sheets were developed for the reduction of alumina content in a lumpy manganese ore from the Joda area [12]. Simple classification and

Chromite ore beneficiation: prospects and challenges

2023年1月1日 Idiomorphic chromite is the only ore mineral appearing in economic quantities. The average content of the ore is 26% Cr 2 O 3 and the Cr/Fe ratio is 1.55. The Kemi chromium mine is an open-pit mine with a waste rock to ore ratio of 5.5:1. At Kemi, the ore from the mine contains 11% iron and 25.5% Cr 2 O 3.

Barite Ore Beneficiation - JXSC Machinery

3 天之前 The composition of barite ore is complex, and there are strict requirements on the fineness of the product in application. The common barite beneficiation process are hand selection, gravity separation,

Siliceous Manganese Ore from Eastern India:A

Siliceous manganese ore, associated with the banded iron formation occurs in large volume in northern Odisha, India. It is a sub-grade ore containing 21% Mn, 60% SiO 2 and 3% Fe, hence do not find any use and

Beneficiation of Manganese Ore Using Froth Flotation

2019年1月1日 Froth flotation is the process generally recommended for the beneficiation of low and medium grade ores because of the floatability characteristics of the manganese. The present work has been taken with waste Manganese ore from Garividi mines (Vizianagaram District). Manganese ores of major commercial importance are pyrolusite

Five Kinds Technology Of Manganese Ore Beneficiation

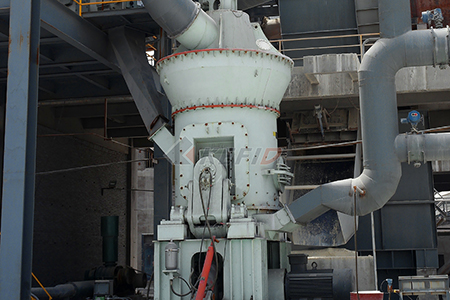

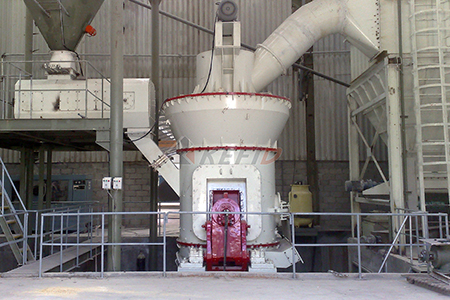

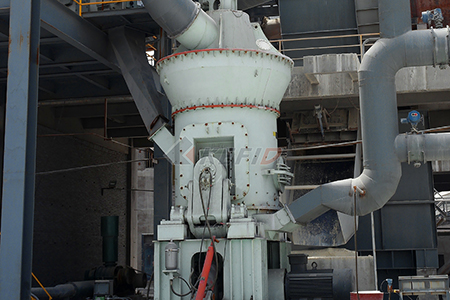

3 天之前 The process involves crushing manganese ore into smaller particles, sorted according to their size. Commonly used equipment includes ball mills, jaw crushers and vibrating screens . Grinding reduces the size of the ore and exposes more surface area, making it easier for chemical reactions to occur during subsequent processing.

Beneficiation and agglomeration process to utilize low-grade ...

2011年5月8日 During mining, beneficiation and transportation of these manganese-bearing ores up to 30% of the ore produced is converted into −10 mm low grade Mn ore fines. Indian manganese ore deposits occur as bedded sedimentary deposits and found in Madhya Pradesh, Maharashtra, Gujarat, Andra Pradesh and Orissa states.

Beneficiation and Processing Technology of Manganese Ore

2019年3月11日 Manganese ore processing has many processes, such as magnetic separation, flotation, gravity separation and so on. In actual production Fodamon adopt, the simple and easy-to-concentrate manganese ...

Bauxite Beneficiation Tailings Reprocessing Process

3 天之前 Processing: The commonly used beneficiation processes for bauxite are ore washing, flotation, magnetic separation, chemical beneficiation, etc., and the tailings can be treated by processes such as tailings wet discharge, dry stacking, and reprocessing. Comprehensive utilization of bauxite tailings: the main chemical components of bauxite ...

Manganese Ore Production Line-Well-tech International

2022年5月30日 manganese ore production line, manganese ore mineral processing, manganese ore process flow, manganese ore mining flow chart, manganese ore mining flow sheet, manganese ore beneficiation method, ... Well-tech International Mining Equipment Co.,Ltd. is a large benefication service company specialized in designing, manufacturing,

Gravity Concentrator Mineral Ore Processing Manganese Benefication

2023年5月21日 Type: Gravity Separator Voltage: 380V Material: Carbon Steel Certification: ISO9001:2008, ISO9001:2000, CE Energy Saving: Energy Saving Warranty: 1 Year

Phosphate Rock Beneficiation Process - JXSC Machinery - Mineral Processing

3 天之前 The phosphate ore processing can be divided into three stages: ... Manganese Ore Process Plant; Lead Zinc Ore Processing; Contact Us +86-18879767229 [email protected] Factory Address: No.16, Gongye Avenue, Guzhang Industrial Park, Ganzhou, Jiangxi, China; Facebook-f Youtube Linkedin Whatsapp

(PDF) Studies on Beneficiation of Manganese Ore

2020年6月20日 In the unsieved ground ore, manganese content of 45% was achieved with a recovery of 23% and Mn/Fe ratio of 19% at a magnetic intensity of 8500 Gauss. At the same operating conditions, SiO2 was ...

CHARACTERIZATION AND BENEFICIATION OF IRANIAN LOW-GRADE MANGANESE ORE

2013年4月26日 The Charagah ore by average grading of 13.8% MnO which implies about 17%. pyrolusite (by considering 81.6% MnO for pyrolusite) as main valuable is one of the. low grade deposits in the world ...

China Mining Spiral Concentrator; Gold Shaking Table; Mine

Ghana Placer Gold Mining Ore Benefication 50 Tph Gold Mining Processing Plant FOB Price: US $5,000-10,000 / Piece Min. Order: 1 Piece

Various Types Of Iron Ore Beneficiation Processes

3 天之前 The beneficiation of various types of iron ore is a complex process that requires careful analysis and planning. Whether it is hematite, magnetite, or any other iron ore, implementing effective beneficiation technology can significantly improve the economic viability of a mining operation. ... Manganese Ore Process Plant; Lead Zinc Ore ...

The Ultimate Guide of Manganese Benefication Mining Pedia

2022年10月13日 A rotary kiln is suitable for processing fine ore. 6. Dewatering. Manganese ore beneficiation mostly adopts gravity separation or strong magnetic separation, and its coarse-grained manganese concentrate is easy to dehydrate and can be dewatered by natural stockpiling, belt transportation, or a screening machine.

Manganese Processing Plant, Equipment - JXSC Machinery

6 天之前 Alluvial Rock Manganese Ore beneficiation Plant. This is a setup of alluvial rock manganese ore process plant, the main equipment including: Capacity: washing 100 TPH, crushing with 200 TPH. 1. Washing part: The vibrating feeder feeds the raw material into a trommel scrubber for scrubbing and washing the clay.

Three Common Beneficiation Process For Lithium Ore

2023年6月8日 Beneficiation is the process of removing unwanted minerals or impurities from ore to increase its value or quality. However, extracting and processing lithium from its ore is challenging due to its complex chemistry and the presence of impurities. Lithium ore beneficiation processes involve crushing, grinding, gravity separation, flotation and ...

Beneficiation and agglomeration of manganese ore fines (an

Beneficiation and agglomeration of manganese ore fines (an area so important and yet so ignored) ... , Volume 285, Mineral Processing and Technology International Conference 2017 23–24 October 2017, Jakarta, Indonesia. Download Article PDF. Figures. Tables. References. 1310 Total downloads. Turn off MathJax Turn on MathJax. Share this article ...